Introduction

In the world of manufacturing, precision and quality are paramount. CW3 part manufacturer, known for their exacting standards and robust performance, play a critical role in various industries. Whether it’s in automotive, aerospace, or industrial machinery, the demand for high-quality CW3 parts continues to grow. This blog will explore the importance of CW3 part manufacturers, the benefits of CW3 parts, and the applications that rely on these precision-engineered components.

The Importance of CW3 Part Manufacturers

Manufacturers specializing in CW3 parts are crucial for several reasons:

Precision Engineering

- CW3 part manufacturers employ advanced machining techniques and state-of-the-art equipment to produce components with precise dimensions and tight tolerances. This precision ensures that the parts fit perfectly and function reliably in their intended applications.

Quality Control

- Rigorous quality control measures are in place to ensure that each CW3 part meets stringent industry standards. From material selection to final inspection, every step of the manufacturing process is closely monitored to guarantee consistency and quality.

Customization

- CW3 part manufacturers offer customization options to meet specific customer requirements. Whether it’s unique dimensions, special finishes, or custom threading, manufacturers can tailor CW3 parts to suit diverse applications.

Innovation

- Leading CW3 part manufacturers invest in research and development to innovate and improve their products. This commitment to innovation ensures that they stay ahead of industry trends and continue to provide high-performance parts that meet evolving demands.

Benefits of CW3 Parts

Corrosion Resistance

- CW3 brass offers excellent resistance to corrosion, making it suitable for use in environments where moisture and chemicals are present. This property ensures the longevity and reliability of CW3 parts.

Machinability

- The addition of lead in CW3 brass enhances its machinability, allowing manufacturers to produce complex and intricate components with ease. This machinability reduces production time and costs.

Strength and Durability

- CW3 parts exhibit high strength and durability, making them ideal for applications that require robust and long-lasting components. This durability ensures that CW3 parts can withstand heavy use and harsh conditions.

Versatility

- CW3 brass is a versatile material that can be used in various applications, from plumbing and electrical components to automotive and aerospace parts. Its adaptability makes it a popular choice across multiple industries.

Applications of CW3 Parts

Automotive Industry

- CW3 parts are used in automotive applications, including fuel systems, braking systems, and engine components. Their strength and corrosion resistance make them ideal for the demanding conditions of automotive environments.

Aerospace Industry

- In the aerospace sector, CW3 parts are employed in aircraft systems, avionics, and structural components. The precision and reliability of CW3 parts are crucial for ensuring the safety and performance of aerospace applications.

Plumbing and HVAC

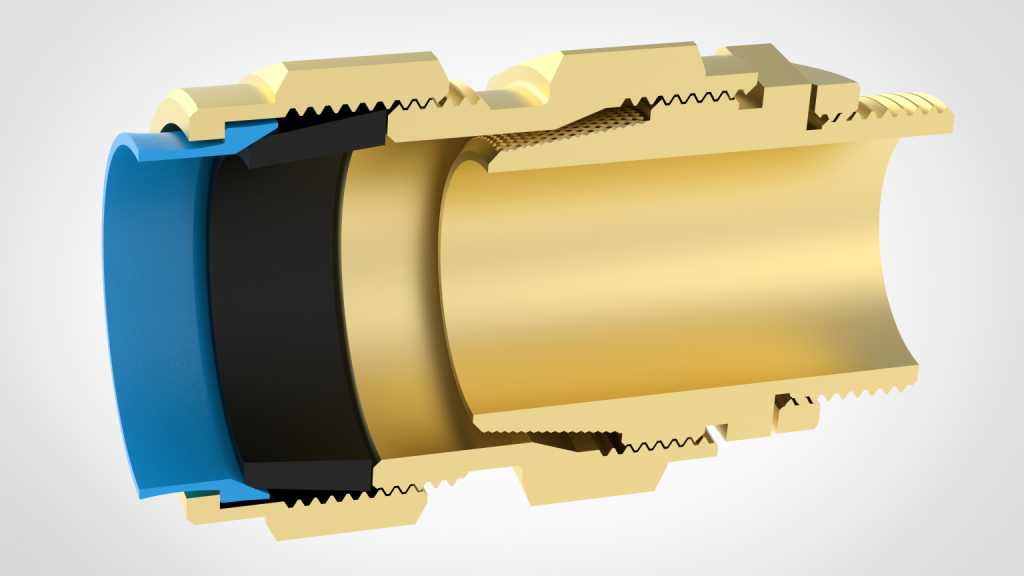

- CW3 brass is commonly used in plumbing and HVAC systems due to its corrosion resistance and durability. CW3 parts, such as fittings, valves, and connectors, ensure leak-free and reliable performance in water and gas systems.

Electrical Components

- CW3 parts are used in electrical connectors, terminals, and switchgear. The excellent conductivity and corrosion resistance of CW3 brass make it an ideal material for electrical applications.

Industrial Machinery

- In industrial machinery, CW3 parts are used in bearings, gears, and fasteners. Their strength and machinability ensure that they perform reliably in high-stress and high-wear conditions.

Choosing the Right CW3 Part Manufacturer

When selecting a CW3 part manufacturer, consider the following factors:

Experience and Expertise

- Look for manufacturers with extensive experience and expertise in producing CW3 parts. A proven track record indicates reliability and capability.

Quality Assurance

- Ensure that the manufacturer has robust quality assurance processes in place. Certifications and compliance with industry standards are good indicators of a manufacturer’s commitment to quality.

Customization Capabilities

- Choose a manufacturer that offers customization options to meet your specific needs. This flexibility ensures that you get the exact parts required for your application.

Customer Support

- Reliable customer support is essential for addressing any queries or issues that may arise. Select a manufacturer known for excellent customer service and support.

CW3 Part Manufacturer FAQs:

What are CW3 parts?

CW3 parts are components manufactured using CW3 brass, a type of brass alloy known for its excellent mechanical properties, machinability, and corrosion resistance. CW3 brass is also known as CZ131 or C35300.

What industries use CW3 parts?

CW3 parts are used in a variety of industries, including automotive, aerospace, plumbing, HVAC, electrical, and industrial machinery. Their versatility and durability make them suitable for numerous applications.

How are CW3 parts manufactured?

CW3 parts are typically manufactured using advanced machining techniques such as CNC machining, casting, forging, and stamping. The process involves precision engineering to ensure tight tolerances and high-quality finishes.

Can CW3 parts be customized?

Yes, CW3 part manufacturers offer customization options to meet specific requirements. Customization can include unique dimensions, special finishes, threading options, and other specific features tailored to your application.

What quality control measures are in place for CW3 parts?

CW3 part manufacturers implement rigorous quality control measures, including material testing, dimensional inspections, and performance testing. These measures ensure that each part meets stringent industry standards and customer specifications.

Conclusion

CW3 part manufacturers play a vital role in supplying high-quality, precision-engineered components that are essential for various industries. Their commitment to precision, quality control, and innovation ensures that CW3 parts meet the demanding requirements of applications ranging from automotive and aerospace to plumbing and electrical systems. By understanding the benefits and applications of CW3 parts, and choosing the right manufacturer, businesses can ensure the reliability and performance of their products. If you have further questions or need specific information, consult with a trusted CW3 part manufacturer for expert advice and high-quality components.