Introduction to A2 Compression Fittings

A2 compression exporter fittings are essential components used in a variety of industries to connect pipes and tubes securely. These fittings are known for their reliability, ease of installation, and ability to withstand high pressure. As a critical part of fluid and gas handling systems, A2 compression exporter fittings ensure leak-proof connections in both domestic and industrial applications. This blog will explore the importance of A2 compression exporter fittings, their manufacturing process, applications, and how to choose a reliable exporter.

What Are A2 Compression Fittings?

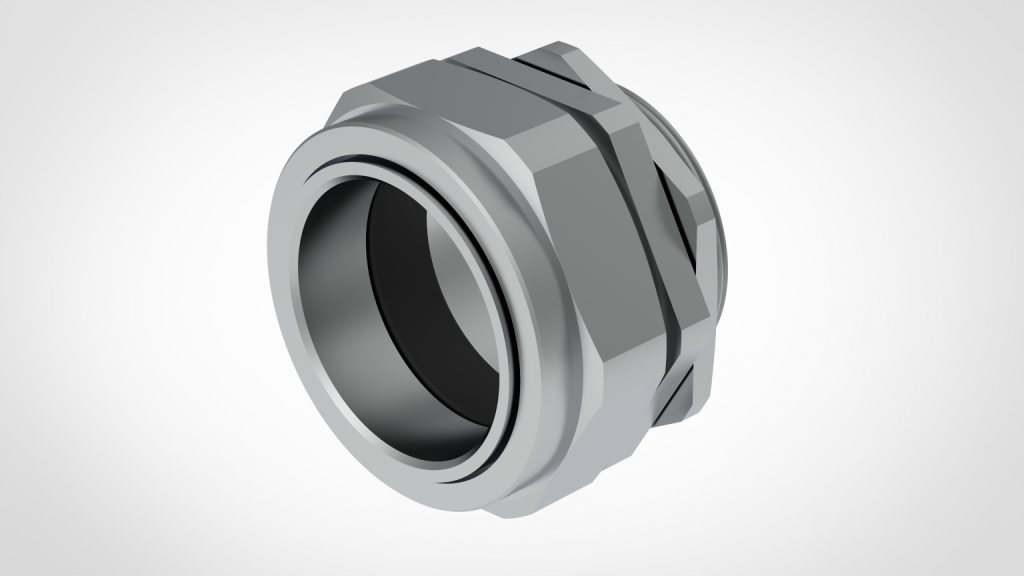

A2 compression exporter fittings are typically made from A2 stainless steel, known for its corrosion resistance and durability. These fittings consist of three main components:

- Body: The main section that holds the pipe or tube.

- Nut: A threaded component that tightens onto the body.

- Ring (or Ferrule): A ring that compresses against the pipe or tube when the nut is tightened, creating a secure seal.

Advantages of A2 Compression Fittings

Corrosion Resistance: A2 stainless steel provides excellent resistance to corrosion, making these fittings ideal for use in harsh environments.

Durability: The robustness of A2 stainless steel ensures long-lasting performance.

Ease of Installation: Compression fittings can be easily installed without the need for soldering or welding, reducing installation time and labor costs.

Leak-Proof: When properly installed, A2 compression fittings offer reliable, leak-proof connections.

Versatility: Suitable for a wide range of applications, from residential plumbing to industrial fluid handling systems.

Manufacturing Process of A2 Compression Fittings

Material Selection:

- High-quality A2 stainless steel is selected for its strength, corrosion resistance, and machinability.

Cutting and Shaping:

- The stainless steel is cut into appropriate sizes and shaped into the required components using precision machining tools.

Threading:

- Threads are cut into the body and nut components using threading machines. The threads must be precise to ensure proper fitting and sealing.

Assembly:

- The body, nut, and ring are assembled to form the complete compression fitting. Each component is carefully inspected to ensure it meets quality standards.

Quality Control:

- Rigorous quality control checks are performed throughout the manufacturing process. These checks include dimensional accuracy, thread integrity, and material composition analysis.

- Finishing:

- The fittings are polished or treated to improve their appearance and corrosion resistance. Common finishes include passivation and electro-polishing.

Applications of A2 Compression Fittings

Plumbing:

- Used in residential and commercial plumbing systems to connect water pipes, ensuring leak-free and reliable connections.

HVAC Systems:

- Essential components in heating, ventilation, and air conditioning systems, providing secure connections for fluid and gas lines.

Industrial Fluid Handling:

- Used in chemical, petrochemical, and pharmaceutical industries for transporting fluids and gases under high pressure.

Automotive:

- Utilized in automotive applications for fuel lines, brake lines, and hydraulic systems, offering reliable and durable connections.

Marine:

- Ideal for marine applications due to their excellent corrosion resistance, ensuring long-lasting performance in harsh environments.

Choosing a Reliable A2 Compression Fittings Exporter

When selecting an exporter for A2 compression fittings, consider the following factors:

Experience and Expertise:

- Choose an exporter with extensive experience and a proven track record in manufacturing and exporting high-quality compression fittings.

Quality Standards:

- Ensure the exporter adheres to international quality standards such as ISO 9001, ensuring that the fittings meet stringent quality and performance criteria.

Customization Options:

- Look for exporters that offer customization options to meet specific application requirements, including different sizes, thread types, and finishes.

Technology and Equipment:

- Opt for exporters that utilize advanced technology and modern equipment, ensuring precision and consistency in the manufacturing process.

Customer Support:

- Consider exporters that provide excellent customer support and after-sales service, offering assistance and addressing any issues promptly.

Global Reach:

- An exporter with a global reach and experience in handling international shipments can ensure timely and efficient delivery of products.

A2 Compression Exporter FAQs:

1. What Are A2 Compression Exporter Fittings?

Answer: A2 compression exporter fittings are connectors made from A2 stainless steel, designed to join pipes or tubes securely. They consist of a body, nut, and ring (ferrule), providing leak-proof connections for fluid and gas systems.

2. What Are the Benefits of Using A2 Compression Exporter Fittings?

Answer: The benefits include corrosion resistance, durability, ease of installation, leak-proof performance, and versatility in various applications such as plumbing, HVAC systems, industrial fluid handling, automotive, and marine environments.

3. Why Is A2 Stainless Steel Preferred for Compression Fittings?

Answer: A2 stainless steel is preferred for its excellent corrosion resistance, strength, and durability. It ensures long-lasting performance in harsh environments and is suitable for high-pressure applications.

4. What Are the Common Applications of A2 Compression Exporter Fittings?

Answer: Common applications include residential and commercial plumbing, HVAC systems, industrial fluid and gas handling, automotive fuel and brake lines, and marine applications due to their corrosion resistance.

5. How Are A2 Compression Fittings Installed?

Answer: A2 compression fittings are installed by sliding the nut and ring over the pipe or tube, inserting the pipe into the fitting body, and tightening the nut. This compresses the ring against the pipe, creating a secure, leak-proof seal without the need for soldering or welding.

Conclusion

A2 compression exporter fittings are essential components in various industries, providing reliable and leak-proof connections for fluid and gas handling systems. Understanding the manufacturing process, applications, and advantages of these fittings can help you make informed decisions when selecting the right product for your needs. By choosing a reputable and experienced A2 compression fittings exporter, you can ensure the quality and reliability of these critical components, contributing to the success of your projects and operations.