Introduction:

CW 3 Part NPT manufacturer fittings are essential components in various industrial and commercial applications, providing secure and leak-proof connections in piping systems. These fittings are designed to meet the rigorous demands of high-pressure and high-temperature environments, making them indispensable in sectors such as oil and gas, chemical processing, water treatment, and more. In this blog, we will delve into the features, benefits, applications, and manufacturing processes of CW 3 Part NPT fittings, highlighting their significance in modern industry.

Features and Benefits of CW 3 Part NPT Fittings

Material Quality:

- CW 3 Part NPT fittings are often made from high-quality brass or stainless steel, providing excellent durability and resistance to corrosion and wear.

- These materials ensure longevity and reliability, even in harsh operating conditions.

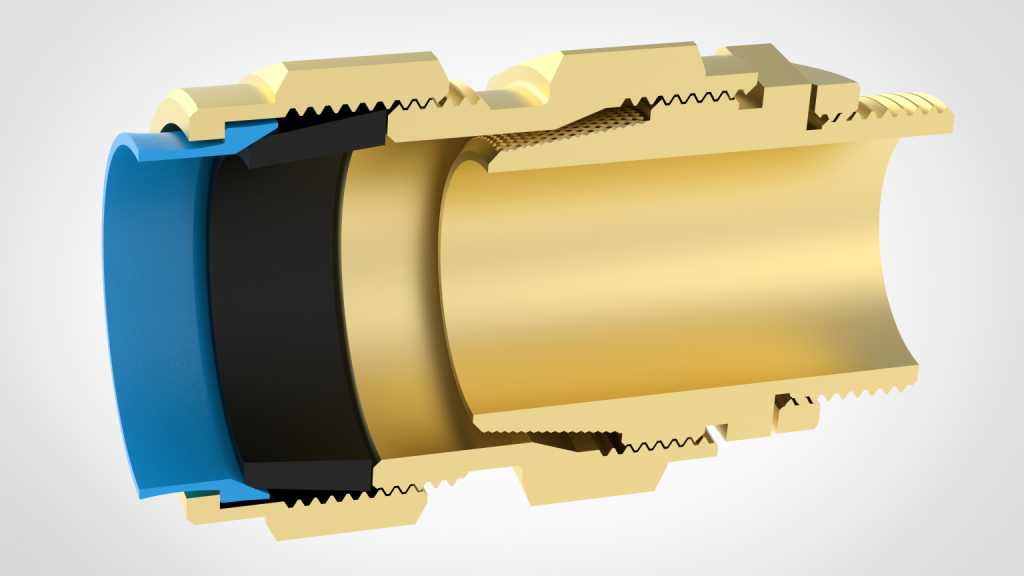

Design and Construction:

- The three-part design typically includes a body, a nut, and a ferrule, which together ensure a secure and leak-proof connection.

- The NPT threads provide a self-sealing feature that is enhanced under pressure, reducing the risk of leaks.

Versatility:

- These fittings are suitable for use in various piping systems, including those for water, gas, oil, and chemicals.

- They can be used in high-pressure and high-temperature environments, making them versatile across many industries.

Easy Installation:

- The design of CW 3 Part NPT fittings allows for straightforward installation and maintenance, reducing downtime and labor costs.

- The tapered thread design ensures a secure fit without the need for additional sealing materials in many cases.

Standards Compliance:

- These fittings comply with stringent industry standards, ensuring safety and reliability in critical applications.

Applications of CW 3 Part NPT Fittings

Oil and Gas Industry:

- Used in pipeline systems to transport crude oil, natural gas, and refined products.

- Essential for maintaining leak-proof connections in high-pressure and high-temperature conditions.

Chemical Processing:

- Ideal for connecting pipes that carry corrosive chemicals and other hazardous materials.

- Their resistance to chemical corrosion ensures long-lasting performance and safety.

Water Treatment:

- Used in water purification and distribution systems to ensure secure and contaminant-free connections.

- Their durability ensures a long service life, reducing the need for frequent replacements.

HVAC Systems:

- Integral in heating, ventilation, and air conditioning systems for connecting various pipes and components.

- Ensure efficient and leak-free fluid and gas flow within the system.

Industrial Manufacturing:

- Used in machinery and equipment that require reliable fluid and gas connections.

- Their robust design ensures they can withstand the rigors of industrial environments.

Manufacturing Process of CW 3 Part NPT Fittings

Material Selection:

- High-quality brass or stainless steel is selected for its mechanical properties and corrosion resistance.

Forging and Machining:

- The material is forged and machined to precise dimensions, ensuring the parts fit together perfectly.

Threading:

- NPT threads are cut into the fitting using precision machinery to ensure a tight and secure fit.

Assembly:

- The three parts (body, nut, and ferrule) are assembled and tested to ensure they work together seamlessly.

Quality Control:

- Each fitting undergoes rigorous quality control checks to ensure it meets industry standards and performance specifications.

CW 3 Part NPT Manufacturer FAQs:

What is a CW 3 Part NPT manufacturer fitting?

A CW 3 Part NPT manufacturer fitting is a type of pipe fitting designed with three components: the body, nut, and ferrule. It uses National Pipe Taper (NPT) threads, which provide a secure, leak-proof connection in fluid and gas systems. The “CW” designation often refers to the material or specific manufacturing standards the fitting adheres to.

What materials are commonly used to manufacture CW 3 Part NPT manufacturer fittings?

CW 3 Part NPT manufacturer fittings are typically made from high-quality materials such as brass or stainless steel. These materials offer excellent durability, corrosion resistance, and strength, making them suitable for various demanding applications.

Why are NPT threads used in these fittings?

NPT threads are used because they provide a secure, self-sealing connection that becomes tighter under pressure. The tapered design of NPT threads ensures a strong grip and reduces the risk of leaks, making them ideal for high-pressure and high-temperature environments.

Are CW 3 Part NPT manufacturer fittings suitable for high-pressure applications?

Yes, CW 3 Part NPT manufacturer fittings are designed to withstand high-pressure applications. The robust construction and the secure NPT threads make them suitable for use in environments where high pressure and temperature are common.

Can CW 3 Part NPT fittings be used in both fluid and gas systems?

Yes, CW 3 Part NPT fittings are versatile and can be used in both fluid and gas systems. Their design and material properties ensure they provide reliable, leak-proof connections in a variety of applications.

Conclusion

CW 3 Part NPT manufacturer fittings are a critical component in many industrial and commercial piping systems, providing reliable and leak-proof connections. Their robust design, high-quality materials, and compliance with industry standards make them suitable for a wide range of applications, from oil and gas to water treatment and HVAC systems. Understanding the features, benefits, and applications of these fittings can help businesses make informed decisions, ensuring the efficiency and safety of their operations.